Product Details

FOCUSING ON HIGH-PRESSURE PUMP SOLUTIONS

Building automation system services

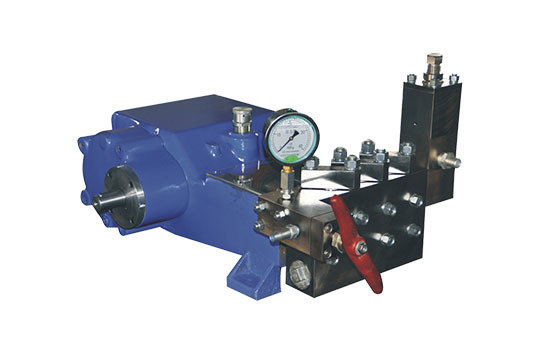

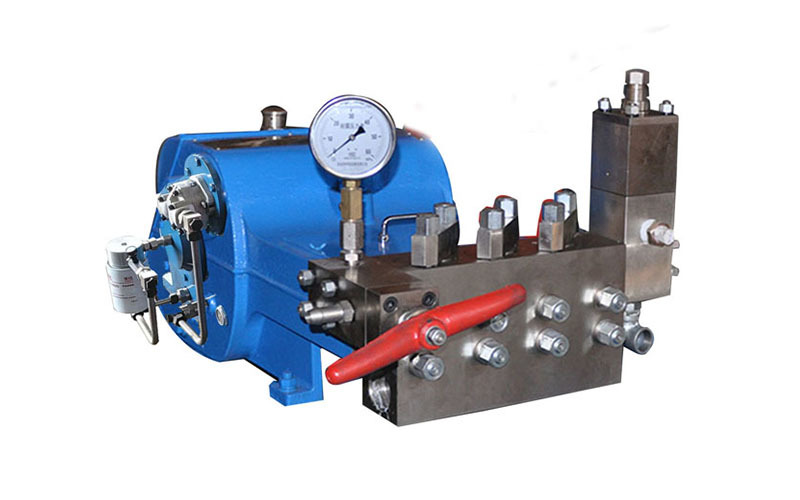

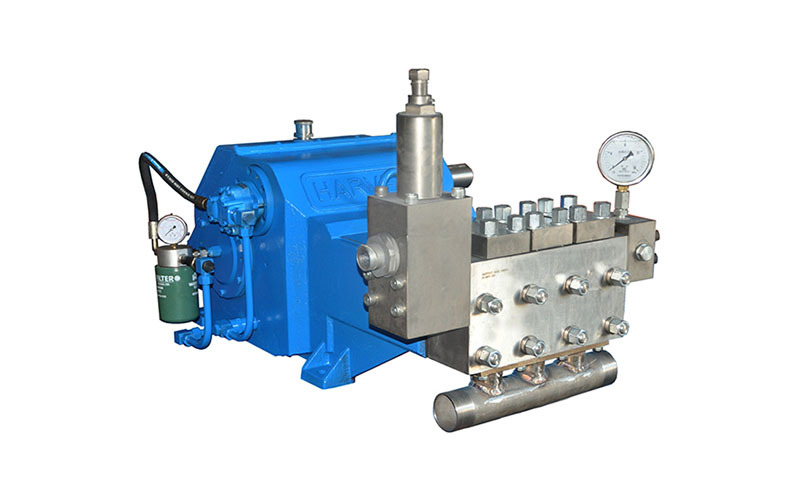

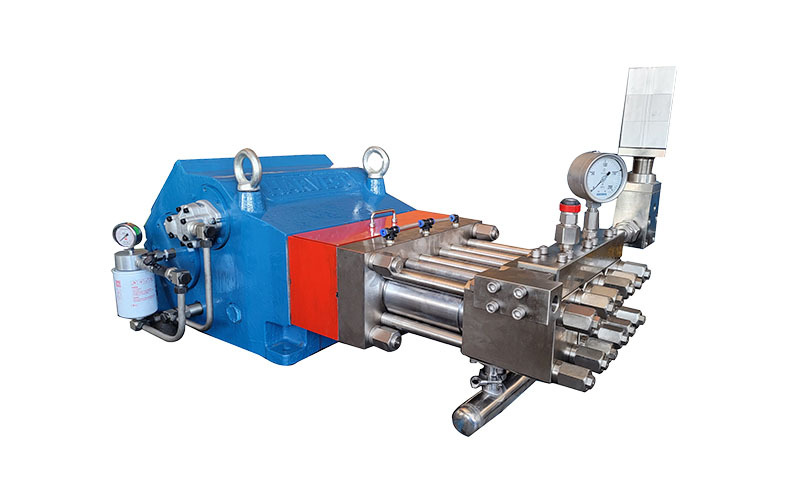

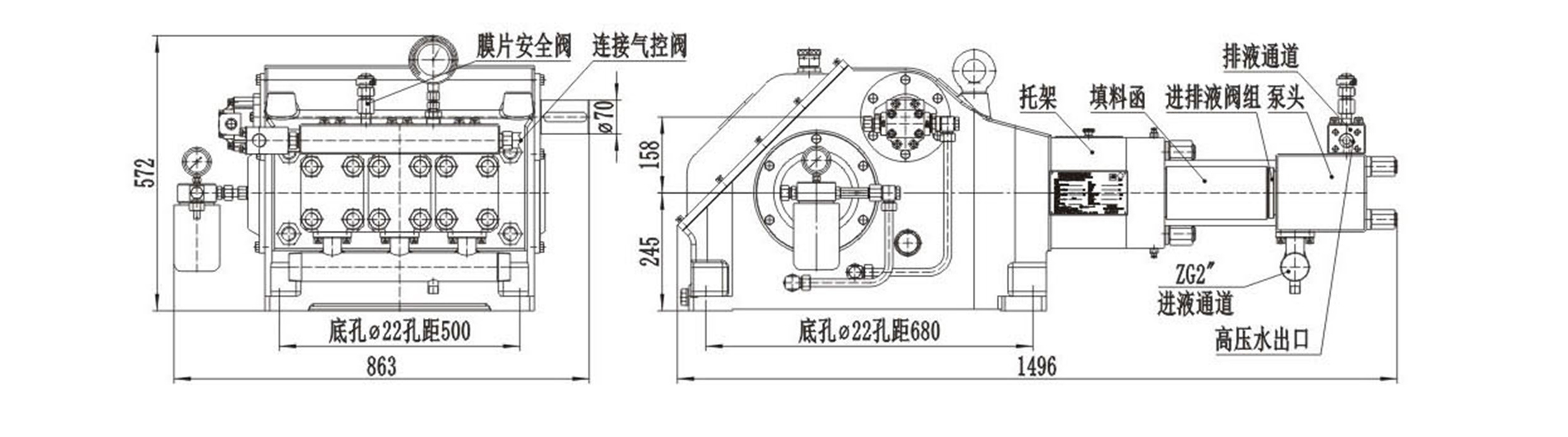

Industrial High Pressure Plunger Pumps HW250D

Pressure range: 35-165MPa

Flow range: 47-138L/min

Specification: 1496*863*572

Keywords:

Industrial High Pressure Plunger Pumps HW250D

Category:

High pressure pump

Accessories:

Hotline:

Industrial High Pressure Plunger Pumps HW250D

Details

HW250D-S series high pressure plunger pumps are based on the new 250D power ends, and match a variety of transmission speed ratios. The liquid end is matched with the new split type, independent research and designed by our company, pressure up to 1600bar, they are new products.

Application industry: building formwork cleaning, power plant heat exchanger, condenser cleaning, powder metallurgy, etc.

Technical parameters:

|

Enter the number of shaft revolutions r/min RPM |

1480 |

Enter the number of shaft revolutions r/min RPM |

1800 |

||||||||||||||

|

Gear reduction ratio i |

3.5 |

Plunger stroke mm |

130 |

||||||||||||||

|

Number of pumps r/min |

423 |

Number of pumps r/min |

514 |

||||||||||||||

|

Power kW |

132 |

160 |

185 |

200 |

220 |

250 |

Plunger |

160 |

185 |

220 |

255 |

280 |

335 |

Power kW |

|||

|

Rated flow |

Rated discharge pressure MPa |

Rated discharge pressure MPa |

Rated flow |

||||||||||||||

|

m³ /h |

L/min |

L/min |

m³ /h |

||||||||||||||

|

3.8 |

63 |

108 |

125 |

150 |

|

|

|

22 |

85 |

95 |

115 |

130 |

150 |

|

76 |

1.6 |

|

|

4.5 |

74 |

85 |

110 |

120 |

135 |

155 |

|

24 |

72 |

85 |

100 |

110 |

125 |

150 |

91 |

5.4 |

|

|

4.8 |

81 |

80 |

100 |

115 |

125 |

140 |

158 |

25 |

65 |

75 |

85 |

100 |

110 |

145 |

98 |

5.9 |

|

|

5.2 |

87 |

75 |

95 |

105 |

115 |

128 |

150 |

26 |

60 |

70 |

80 |

95 |

108 |

142 |

106 |

6.4 |

|

|

5.7 |

94 |

70 |

88 |

100 |

110 |

120 |

140 |

27 |

55 |

65 |

77 |

90 |

102 |

140 |

115 |

6.9 |

|

|

6.1 |

101 |

65 |

85 |

92 |

100 |

110 |

130 |

28 |

50 |

60 |

70 |

85 |

92 |

115 |

123 |

7.4 |

|

|

7.0 |

116 |

58 |

75 |

83 |

90 |

96 |

112 |

30 |

40 |

50 |

60 |

75 |

82 |

90 |

142 |

8.5 |

|

|

7.9 |

132 |

52 |

64 |

72 |

80 |

87 |

100 |

32 |

35 |

45 |

55 |

65 |

72 |

80 |

161 |

9.7 |

|

|

Weight : single pump 910kg Base 220kg Inlet ZG2" High pressure water outlet UNF1 1/8"-12 |

|||||||||||||||||

|

Enter the number of shaft revolutions r/min RPM |

1480 |

Enter the number of shaft revolutions r/min RPM |

1800 |

||||||||||||||

|

Gear reduction ratio i |

4.086 |

Plunger stroke mm |

130 |

||||||||||||||

|

Number of pumps r/min |

362 |

Number of pumps r/min |

441 |

||||||||||||||

|

Power kW |

132 |

160 |

185 |

200 |

220 |

Plunger |

160 |

185 |

220 |

255 |

280 |

335 |

Power kW |

||||

|

Rated flow |

Rated discharge pressure MPa |

Rated discharge pressure MPa |

Rated flow |

||||||||||||||

|

m³ /h |

L/min |

L/min |

m³ /h |

||||||||||||||

|

3.2 |

54 |

125 |

155 |

|

|

|

22 |

100 |

110 |

130 |

160 |

|

|

65 |

3.9 |

||

|

3.8 |

64 |

107 |

125 |

150 |

160 |

|

24 |

85 |

93 |

110 |

130 |

150 |

160 |

78 |

4.7 |

||

|

4.2 |

69 |

96 |

115 |

136 |

155 |

160 |

25 |

78 |

85 |

100 |

120 |

140 |

158 |

84 |

5.1 |

||

|

4.5 |

75 |

90 |

105 |

125 |

145 |

150 |

26 |

70 |

80 |

95 |

115 |

130 |

150 |

91 |

5.5 |

||

|

4.8 |

81 |

85 |

100 |

118 |

125 |

140 |

27 |

65 |

75 |

90 |

108 |

120 |

137 |

98 |

5.9 |

||

|

5.2 |

87 |

80 |

95 |

108 |

120 |

130 |

28 |

60 |

70 |

85 |

100 |

110 |

128 |

106 |

6.4 |

||

|

6.0 |

100 |

70 |

83 |

98 |

105 |

113 |

30 |

52 |

60 |

70 |

85 |

96 |

112 |

122 |

7.3 |

||

|

6.8 |

113 |

60 |

75 |

85 |

92 |

100 |

32 |

45 |

52 |

62 |

75 |

85 |

95 |

138 |

8.3 |

||

|

Weight : single pump 910kg Base 220kg Inlet ZG2" High pressure water outlet UNF1 1/8"-12 |

|||||||||||||||||

|

Enter the number of shaft revolutions r/min RPM |

1480 |

Enter the number of shaft revolutions r/min RPM |

1800 |

|||||||||||||

|

Gear reduction ratio i |

4.619 |

Plunger stroke mm |

130 |

|||||||||||||

|

Number of pumps r/min |

320 |

Number of pumps r/min |

390 |

|||||||||||||

|

Power kW |

132 |

160 |

185 |

200 |

Plunger |

160 |

185 |

220 |

255 |

280 |

335 |

Power kW |

||||

|

Rated flow |

Rated discharge pressure MPa |

Rated discharge pressure MPa |

Rated flow |

|||||||||||||

|

m³ /h |

L/min |

L/min |

m³ /h |

|||||||||||||

|

2.8 |

47 |

130 |

150 |

|

|

22 |

110 |

125 |

140 |

160 |

|

|

58 |

3.5 |

||

|

3.4 |

56 |

110 |

150 |

165 |

|

24 |

95 |

100 |

120 |

145 |

160 |

|

69 |

4.1 |

||

|

3.7 |

61 |

105 |

130 |

150 |

160 |

25 |

88 |

95 |

110 |

135 |

150 |

160 |

75 |

4.5 |

||

|

4.0 |

66 |

100 |

120 |

140 |

150 |

26 |

80 |

90 |

100 |

125 |

140 |

150 |

81 |

4.8 |

||

|

4.3 |

71 |

95 |

115 |

135 |

140 |

27 |

75 |

85 |

95 |

120 |

132 |

142 |

87 |

5.2 |

||

|

4.6 |

77 |

88 |

110 |

125 |

130 |

28 |

70 |

80 |

90 |

110 |

122 |

132 |

94 |

5.6 |

||

|

5.3 |

88 |

78 |

95 |

105 |

113 |

30 |

60 |

70 |

80 |

96 |

105 |

115 |

107 |

6.4 |

||

|

6.0 |

100 |

68 |

83 |

90 |

100 |

32 |

53 |

62 |

70 |

85 |

95 |

102 |

122 |

7.3 |

||

|

Weight : single pump 910kg Base 220kg Inlet ZG2" High pressure water outlet UNF1 1/8"-12 |

||||||||||||||||

Dimensions:

Industrial High Pressure Plunger Pumps are essential equipment in many industrial applications. These pumps are designed to handle high pressure fluids and are widely used in industries such as oil and gas, chemical, power generation, and water treatment.An industrial high pressure plunger pump typically consists of a cylinder, plunger, and valves. The plunger moves back and forth inside the cylinder, creating a pumping action that forces fluid through the valves and out of the pump. The valves control the flow of fluid and ensure that it is directed to the correct destination.

One of the key features of industrial high pressure plunger pumps is their ability to handle high pressure fluids. These pumps can operate at pressures up to several thousand bar, making them ideal for applications where high pressure is required. In addition to handling high pressure fluids, industrial high pressure plunger pumps are also designed to be durable and reliable. They are typically made from high-quality materials that can withstand the rigors of industrial use. These pumps are also designed to be easy to maintain and repair, ensuring that they can operate at peak performance for long periods of time.

Another important feature of industrial high pressure plunger pumps is their versatility. These pumps can be used to pump a wide variety of fluids, including water, oil, chemicals, and slurries. They can also be customized to meet the specific needs of individual applications, making them a flexible solution for many industrial processes. Overall, industrial high pressure plunger pumps are an important part of many industrial processes. They offer a reliable, efficient, and versatile solution for handling high pressure fluids. If you are looking for a high-quality industrial pump, consider an industrial high pressure plunger pump from a reputable manufacturer. With their durability, reliability, and performance, these pumps are sure to meet your needs.

Releate Products

Inquiry

We will contact you within one working day. Please pay attention to your email.